For the coming season, Smith has the All-Mountain re-designed Forefront 2 with improved ventilation, coverage and goggle and sunglasses carrying capabilities. In the sunglasses world, the new Wildcat has a hybrid-construction cylindrical lens while the performance-oriented Reverb and Ruckus get a much-desired re-design of the PivLock interchangeable shield system.

Forefront 2 Helmet

An evolution of Smith’s award-winning Forefront helmet, the completely re-designed Forefront 2 is a full coverage helmet ideal for all-mountain riders who demand superior protection, wearability, ventilation, and eyewear integration. Evolving its commitment to exceeding protection standards for all-mountain riders, Smith continues its use of proven, lightweight Aerocore™ in-mold construction featuring Koroyd® to provide integrated skeletal structure and complete ventilated protection.

The use of Koroyd® has been extended into the back of the helmet, fully encompassing the head to buffer from injury and impact. Featuring 20 optimized vents, the Forefront 2 also utilizes internal air channels that combine with open intake and exhaust ports to maximize ventilation, while AirEvac™ channels promote airflow to prevent fogging when worn with performance eyewear and goggles.

For ultimate eyewear integration, the Forefront 2 also features channels on the front and rear of the helmet for sunglass storage, and a three position visor that pivots upward for complete goggle storage under the brim. All seven colorways are featured with a multi-directional impact protection system (MIPS®) lining that reduces rotational forces that the brain is exposed to during oblique impacts to the head. Smith helmets are created to absorb direct impacts efficiently, and when combined with MIPS, the helmet liner is separated from the head by a low-friction slip plane that allows the head to slide during impact and may reduce instances of traumatic brain injuries. Select colors (Matte White, Matte Black, and Matte Gravy) are also available without MIPS. Additional features include the VaporFit™ adjustable fit system, XT2® anti-bacterial performance lining, ultralight single layer webbing, and camera and light mount compatibility.

The new Forefront 2 helmet (MSRP $200, $230 with MIPS) will be available in limited colorways August 2018, with the full range of colors in February 2019, at select specialty retailers and online at smithoptics.com.

Wildcat Sunglasses

Charge any trail in the new Wildcat, a hybrid-construction cylindrical lens sunglass designed within Smith’s VELOCITY Collection of performance eyewear. Constructed from durable TR90 and flexible TPU used in Smith goggles, the Wildcat provides extra-large coverage and protection like a goggle with the airflow and comfort of a sunglass. The Wildcat offers riders exceptional versatility with an interchangeable Everday ChromaPop™ lens to reveal natural color, enhance visual clarity and provide greater definition of objects and a clear lens for low light, overcast days, or when riding under tree canopies. Both lens options are equipped with dirt, dust, and grease resistant coatings. With its multi-adjustable nosepiece, the goggle-style frame can be moved closer or further from the face to adjust airflow, while also offering a customizable fit. The nosepiece and temples are comprised of megol which reacts to perspiration by gently adhering to the skin for a comfortable, no-slip fit. Replacement lenses will also be offered in Clear ($40) and ChromaPop ($80) options. The Wildcat (MSRP $199 including two lenses and a hard case) will be available August 2018 at select retailers and online at smithoptics.com.

Reverb and Ruckus Sunglasses

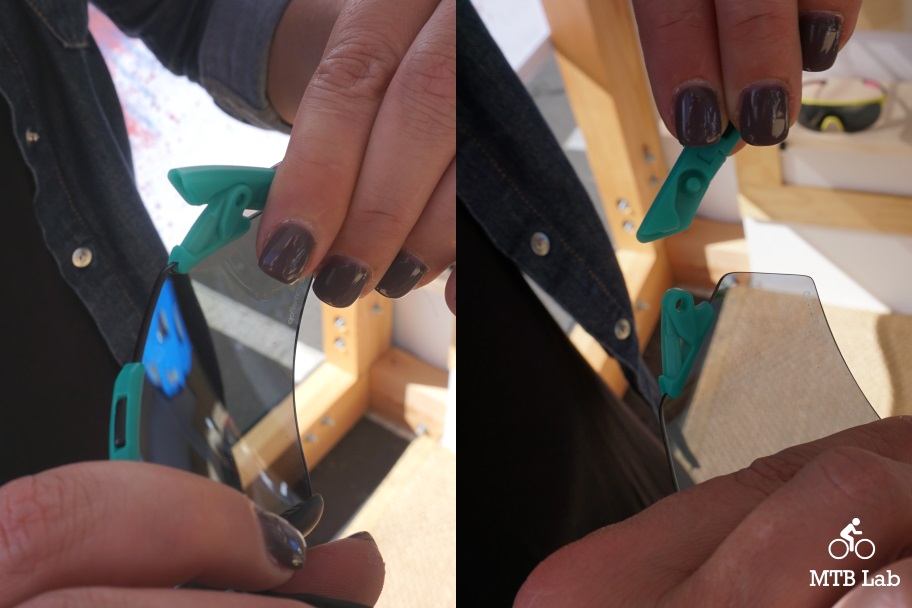

Among its growing VELOCITY Collection of performance eyewear, Smith introduces two new interchangeable shield options featuring re-engineered PivLock™ technology, with the Ruckus and Reverb sunglasses. Designed with a 7 x 4 toric lens curvature, each model provides an unobstructed field of view and amplified color and visual clarity through ChromaPop™ lens technology. The PivLock™ Ruckus features a large coverage fit with raised brow design to increase peripheral vision in the riding position. The addition of top bar venting and dual-position nose pads provide a proper fit to minimize fogging and maximize comfort during long rides and steep climbs. The slightly smaller PivLock™ Reverb echoes performance features of the Ruckus while offering medium coverage with open-brow design and softer lens curve for a unisex fit and feel. At 27 grams, the Reverb is the lightest weight shield in Smith’s VELOCITY sunglass collection. Each model is offered in five ChromaPop performance lens options – that reveal natural color, enhanced visual clarity and greater definition of objects – and all include a secondary ChromaPop Contrast Rose lens for addressing low light conditions.

Both frames include a multi-adjustable nosepiece to allow for added airflow by positioning the frame closer or further from the face, while also offering a customizable fit. The nosepiece and temples are comprised of megol which reacts to perspiration by gently adhering to the skin for a comfortable, no-slip fit at any speed. The thin megol temples also offer ultimate helmet compatibility by securely storing within the open venting channels when taken off the face. Replacement lenses will also be offered in Clear ($40), ChromaPop ($80) and Photochromic ($100) options. The Ruckus and Reverb (MSRP $189 including two ChromaPop performance lenses and hard case) will be available August 2018 at select retailers and online at smithoptics.com.

For further information refer to smithoptics.com.

{ 0 comments… add one now }