During the Outdoor Retailer Ski show this past week, Colorado Based Guerrilla Gravity bicycle company introduced a brand new carbon-fiber lineup that utilizes their unique and highly innovative Revved technology. It continues in their trend of a Made-in-America mountain bike, and the affordable $2,440 pricing with a RockShox Deluxe RT shock will make it a real winner.

Revved Carbon Technology is the bike industry’s newest and most advanced carbon fiber innovation. Covertly in development and testing for the last three years, Revved combines a revolutionary, patent-pending manufacturing process and evolved carbon fiber material to create the next generation of mountain bikes.

For further information refer to ridegg.com.

Luis Benitez, the director of the Colorado Outdoor Recreation Industry Office, gave the opening speech during the product announcement at the Marquis Theater in downtown Denver. Luis was helpful in securing a $250,000 Research and Development grant for the company to bring this technology to fruition, with ffunds coming from the Colorado Office of Economic Development and International Trade and other investors.

After Luis gave a short speech on things, Guerrilla Gravity President Will Montague introduced the new carbon-fiber based bike lineup and went into details about the technology, features, pricing, and models. He emphasized three critical components for the Revved Carbon Technology to make it feasible for them to produce: its toughness, cost and of course Made in America.

They utilize their Freedom Linkage which provides a wide range of tuning options for both air and coil shocks. The versatile platform gives you the freedom to tune the suspension characteristics based on your local terrain and riding style by utilizing an integrated flip chip for Crush Mode and Plush Mode.

The frames have an integrated external cable routing which is hidden behind a cover making for easy maintenance-friendly access and changes, and clean lines. At the bottom of the front triangle is a storage system so you can attach things like tubes, tools, and other items, while underneath the top tube is a water bottle location.

Their Modular Frame Platform features a unified front triangle with their GeoAdjust Headset system with its unique adjustable top and bottom cups so you can alter the reach and wheelbase of the frame by 10mm. They also have optional Seatstay Tuning Kits to allow further tuning of your bike for varying ride styles and terrain, meaning you can make your Trail Pistol into The Smash (you’d need different shock and forks).

The current aluminum full-suspension bike lineup, The Smash, Megatrail, Trail Pistol, and Shred Dog, will all retain their same names, but go forward will only be made as carbon framesets. The bike framesets will range from $2440 to $3275 depending on chosen shock, with kits from $3695 to $5995 (depending on model and build options). For efficiency purposes, all the models will use the same frame and come in 1, 2, 3 and 4 sizes (small to XL).

Compared to the leading types of traditional carbon fiber material, Revved’s material is over 300% more impact resistant, yet matches the strength and stiffness of the traditional material by sharing its continuous-fiber composition. It is part of a new family of materials at the leading edge of aerospace manufacturing. These materials are quickly gaining adoption for use in high-profile projects, most notably within a significant portion of the structural components of Boeing’s new 787.

Technology:

- Impact resistance is greatly increased compared to traditional carbon, even before installing the downtube protector.

- Revved frames are able to use a powder coat finish that is more durable than the wet-paint finish of traditional carbon frames.

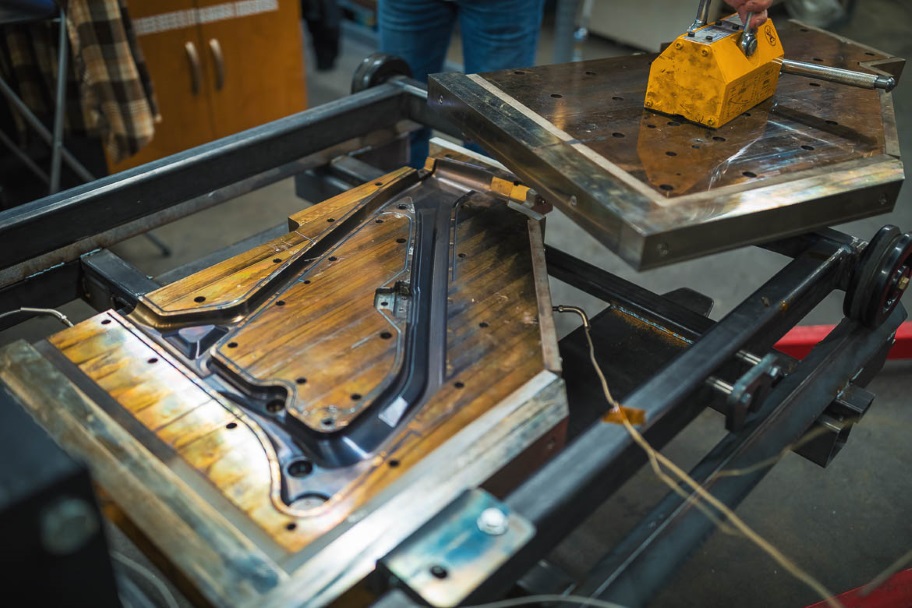

Their new production line is unlike anything you’ll see at another carbon fiber factory—overseas, or in the USA. It’s a new, ground-up process that required significant infrastructure investments in order to make cutting-edge tooling and expand their lean manufacturing capabilities. The result is a new level of efficiency that has enabled us to dramatically increase our capacity, getting more riders on trails faster.

American-made ingenuity:

- Automated fiber placement reduces labor time by approximately 80% while also ensuring quality consistency from one frame to the next.

- These consistency improvements eliminate the defects that occur with traditional carbon fiber during the initial hand-layup process (due to human error).

- Unlike traditional carbon frames that are cured in a 2-4 hour cycle, Revved frames are fused during a 30-minute cycle.

- With a nearly perfect post-mold surface finish, 90% less sanding and finishing work is needed compared to the traditional carbon fiber manufacturing process.