Premium Hub for MK4 and Carbon Wheels

BIG FLATS, NY (January 10, 2022) – In a world filled with chaos, division, and uncertainty, Stan’s would like you to know we’ve made a really nice set of hubs. Seriously, we went all-in on this. Designed and refined over the past two years, the new M-pulse hubs combine quality materials and construction with a smarter engagement system. These new hubs won’t solve the world’s biggest problems, but they will offer years of reliable engagement and less resistance than conventional pawl and ratchet-style hubs.

What’s So Special About the New Hubs?

In a word: magnets. Yes, we’re talking about the same things that power Iron Maiden’s amplifiers and let billionaires’ electric trucks tow around their rocket ships (which also use magnets).

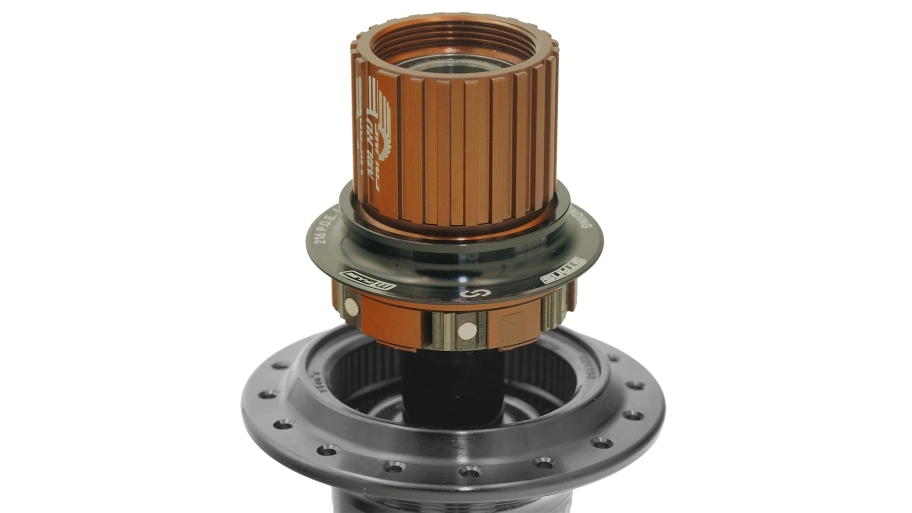

The heart of the M-pulse hub is a bombproof locking engagement system with six pawls equipped with Neodymium rare earth magnets. With 216 points of engagement, M-pulse hubs need only 1.66° of rotation to start putting power to the rear wheel. When engaged, multiple teeth on each pawl lock into a hardened steel ratchet ring while each pawl’s magnet ensures perfect alignment. This not only lets M-pulse freehubs engage more reliably and consistently than traditional spring-based pawl designs but also provides an even more important advantage: less friction and rotational resistance when not engaged. Less friction holding you back means more you going fast and with less effort.

The M-pulse engagement system is based on the innovative Project321 magnetic pawl design, and all freehub body shells, magnetic pawls, ratchet rings, spacers, and axles are manufactured at Project321’s small-batch CNC shop in Bend, Oregon. Each M-pulse hub is then assembled entirely at Stan’s headquarters in Big Flats, New York. Machining the key M-pulse components in the U.S. and assembling the hubs ourselves in New York allows a higher degree of precision, attention to detail, and quality control.

Why Are Magnets Better?

All hubs suffer from momentum-robbing drag as you coast, but when it comes to creating the most efficient and reliable ratchet system, pulling is better than pushing. Conventional mechanical pawl springs are constantly attempting to push the pawls into the ratchet ring. Those push springs are weakest when fully extended, as the teeth of the pawl engage with the teeth of the ratchet ring, but as you coast and the teeth of the pawl disengage and move down out of the teeth of the ratchet ring, push springs compress and exert even more pushing force. This creates significant drag and friction.

Unlike these inefficient mechanical push spring systems, M-pulse hubs use the pull force of Neodymium magnets to reduce drag to the absolute minimum, while still being able to engage with reliable precision the instant you push on a pedal. Magnetic pull springs are at their strongest when the pawl is engaged and are weakest during coasting, the ideal scenario to reduce drag. Project321’s patent-pending placement of the powerful but small rare earth magnets let the pawls self-align quickly and consistently during engagement while creating a hub with almost no rotational resistance when coasting.

Note: Stan’s engineers added an innovative retention clip thingie to hold on the pawls. If you used the already excellent stock P321 system, you had to add lube so that the pawls wouldn’t fall out of place when performing maintenance.

The M-pulse hub’s six magnetic pawls and hardened steel ratchet ring are also built to outlast conventional mechanical springs, which can fatigue, lose tension, and become misaligned over time. With better durability, stronger engagement, and less drag, the M-pulse design is a better way to build a hub.

More Than Just Smart

Because an innovative design is only as good as its materials and construction, each detail of the M-pulse hub has been engineered to systematically eliminate weaknesses found in traditional pawl and ratchet-style hubs. The new M-pulse hub starts with the most simple and durable version of Project321’s magnetic pawls and features an all-new freehub body and main seal design for outstanding protection from the elements. Every bearing on the M-pulse hub is shielded, meaning no bearing seal is directly exposed, for smooth rolling in all conditions and increased bearing life. The 17mm axles are made of 7075 aluminum and roll on long-lasting Enduro brand bearings that feature custom-tuned grease fills that reduce resistance. A double-row main freehub bearing was chosen after tests proved it to be more durable than two individual, separate bearings. Multiple teeth on each pawl provide a greater surface area to distribute the load to improve engagement, and the angle of the pawls was optimized to distribute stress away from the rotating bearings for added durability under high torque.

Beyond the strength and speed of engagement, M-pulse hubs feature adjustable preload that decreases drag and resistance for less effort and more speed. Adjustable preload also prolongs bearing life by allowing the hub’s bearing tension to be tuned with greater precision in contrast with most hubs that tension unevenly by relying solely on how much the bike’s axle has been tightened. A precision piece of equipment deserves the option of precise tuning, and the M-pulse hub’s adjustable preload, available on both the front and the rear hub, delivers that level of tuning precision.

With their quality materials and construction, M-pulse hubs are backed by a 5-year warranty.

The Perfect Match for MK4 Asymmetric Rims

M-pulse hubs are available as complete wheelsets (MSRP starting at $965) laced to the MK4 asymmetric rims, including the 30mm wide Flow MK4, 28mm wide Arch MK4, and 25mm wide Crest MK4 that were all launched last summer. With flanges optimized to better balance spoke tension on each side of the rim, M-pulse hubs allow a single spoke length to be used for an entire matched MK4 wheelset. When it comes to ease of maintenance, nothing beats being able to use the same spoke length for every repair. All wheels continue to rely on traditional J-bend spokes, the most commonly available spokes that are easy to find, should you ever need a replacement.

All carbon CB7 and the Podium SRD series wheelsets (MSRP starting at $1,987) will also roll on the new M-pulse hubs.

However, M-pulse hubs will not be available on the downhill and enduro-ready EX3 and on the more affordable S2 series wheels. Both are built with the E-sync hubs introduced last June.

M-pulse hub options include Shimano Micro Spline, HG, or SRAM XDR freehubs, in 6-bolt or Centerlock brake style, and configurations to fit all popular through-axle widths.

All wheelsets equipped with M-pulse hubs are also part of Stan’s Connection program. With each wheelset registration, we’ll donate $10 to support the local trail group or cycling-related charitable organization of your choice.

Initially, wheels with M-pulse hubs will be available through local and online bike shops. Eventually, consumers will also be able to purchase online directly from Stan’s.

For more information, visit www.NoTubes.com.

ABOUT STAN’S NOTUBES

Stan’s NoTubes, founded and owned by Stan and Cindy Koziatek, set the industry standard for making mountain bikes tires tubeless. Using his exceptional ingenuity, Stan Koziatek devised the original NoTubes sealing system in 2001, the same system that today has become the preferred tubeless conversion system around the world.

Stan’s NoTubes currently designs, produces, and sells innovative mountain bike and gravel wheels and rims as well as a range of products for tubeless conversion.

For more information, visit www.NoTubes.com.