Trek and Bontrager have partnered with WaveCel to create a helmet technology that they say disrupts 30 years of accepted safety standards, and is the biggest advancement in the protection against cycling concussions.

Standard foam helmets are designed to protect against direct impacts. But WaveCel accounts for how most cycling accidents actually happen: ungracefully, with twists, turns, and angled impacts.

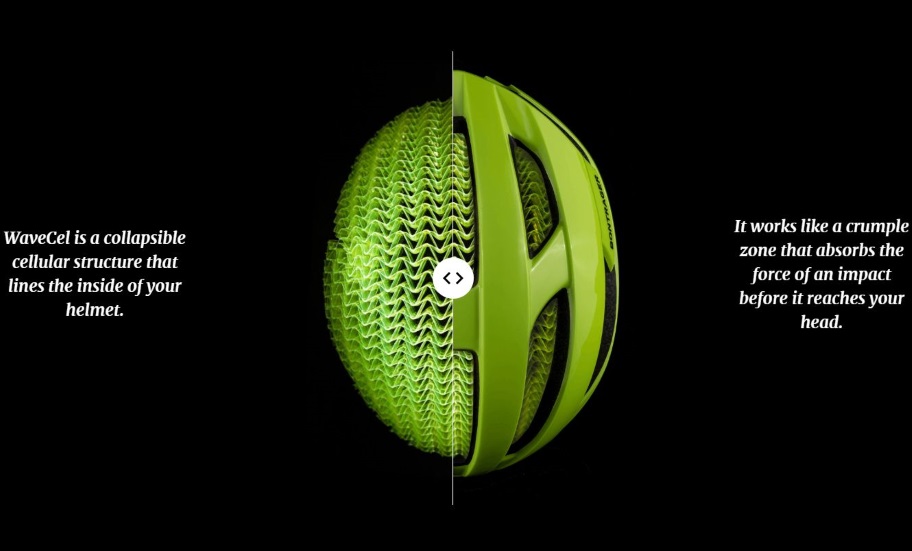

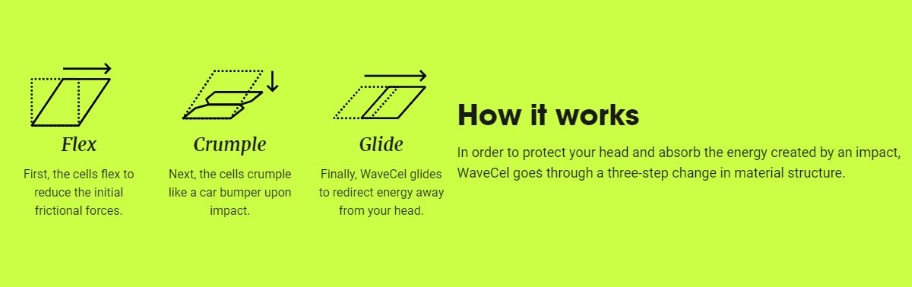

Their new helmet designs utilize a new technology that Bontrager is licensing called Wavecel. It’s a 15mm thick grid of layered can cellular polyester that can crumple, flex, and glide on impact to reducing forces to the head. It is still combined with a standard retention and strap system, is covered with a thinner layer of EPS foam along with a polycarbonate shell.

For further information refer to trekbikes.com.

WaveCel is a helmet safety tech that’s available exclusively in these Bontrager helmets, for the road, mountain, commuter, and e-bike usage, all of which should be remarkably effective at preventing concussions caused by common cycling accidents.

The helmet technology that’s up to 48x more effective at preventing concussions – Results based on AIS 2 Injury (BrIC) at 6.2 m/s test at 45° comparing a standard EPS Helmet and the same helmet modified with WaveCel insert as described in detail in Comparison of Bicycle Helmet Technologies in Realistic Oblique Impacts.

All WaveCel helmets received the highest rating from Virginia Tech’s third-party testing facility. This unbiased assessment proved Bontrager’s WaveCel helmets to be among the highest level of protection available to cyclists with a 5-STAR rating.

WaveCel is a collapsible cellular material that’s supposedly incredibly effective at preventing concussions caused by common cycling accidents. It works by going through a three-step change in material structure on impact to absorb energy before it reaches your head.

This Bontrager-exclusive material is the brainchild of Michael Bottlang, Ph.D. a biomechanical engineer and Steven Madey, MD an orthopedic surgeon who wanted to solve the problem of traumatic brain injuries in active people. It’s the first advanced helmet technology ever to receive funding from the US National Institute of Health.

Check out the full study to learn more about WaveCel and the biggest advancement in the protection against cycling concussions. You’ll never want to ride in anything else.

My thoughts:

According to the brand’s testing, WaveCel helmets prevented concussions in common cycling accidents “nearly 99 times out of 100” and 48x more effective at preventing concussions. Plus, “a major innovation in a category that has remained largely unchanged in 30 years” and “the most advanced helmet technology ever designed.”

Sorry, I call BS on that one, though I’d just call the statements very ambiguous and in a strange ether land of factuality.

I’ve been involved in the technology of helmets, and it’s a been a huge passion and interest of mine for a long time, and the WaveCel technology evolves things, but I still don’t consider it a game changer or revolutionary (marketing hyperbole.)

How did they determine this? With an actual human skull/brain? I don’t they reinvented the helmet, looks very much like another design like the Koroyd technology which Smith uses on their helmets, though Koroyd does need to use MIPS, while the WaveCel has the slip liner for rotational forces integrated as part of its design. WaveCel still uses EPS as a top layer and a plastic outer shell, both of which are old technology.

Of course, I am glad to see any additional innovations, materials, and evolution in helmet designs. They used statistics, engineering and math to come up with their concussion and impact analysis, meaning it’s all simulation and research, which may or may not have actual validity in the real world, but it’s also about all we have. I am a realist and real-world facts would be nice!

The current safety standards for helmets include a retention system, and an impact test, the latter is done using a hard headform dropped vertically onto a flat and shaped anvil at specific speeds and angles. Also, there are some temperature variants required to complete the test. The US standard (CPSC or Consumer Product Safety Commission) is to keep the g forces registered inside the headform below 300 g.

The major components of a helmet, are the outer shell, the foam liner, the retention system, and the padding. The hard shell helps spread the impact over a larger surface (specifically to the liner), accentuates sliding and prevents object penetration. The EPS foam helps prevent or reduce brain injury by managing the energy of an impact through its own compression or destruction, and it does that by converting a small part of the crash energy to heat. Its primary duty is to slow the stopping process so that the head slows down during its inertial of the impact (deceleration).

Polystyrene 101

Polystyrene (Poly(1-phenylethane-1,2-diyl)), abbreviated as PS, is a polymer made from the aromatic monomer styrene (vinyl benzene ), a liquid hydrocarbon that is commercially manufactured from petroleum by the chemical industry. Polystyrene and its origin can be traced back to 1839 when Eduard Simon, an apothecary (pharmacist), distilled an oily substance from a Turkish sweetgum tree, which he named styrol. About one hundred years passed, and various scientists conducted numerous experiments before German chemist Hermann Staudinger discovered that heating styrol starts a reaction and produces macromolecules, this substance is now known as polystyrene. BASF began commercial manufacture of polystyrene in 1931 when they were part of the large German conglomerate I.G Farben (BASF, Bayer, Hoechst, Afga, etc.). Post World War II the I.G Farben conglomerate was divided back up into the individual companies, and in 1952 BASF invented expandable polystyrene (EPS), which they called Styropor. An interesting adjunct is that Bayer developed Makrolon polycarbonate (used as the outer shell of the helmet) around the same period.

Things have improved and gotten more complex with helmet designs since most of them incorporate a slip-plane technology to help reduce rotational motion by absorbing and redirecting rotational energies and forces transferred to the brain from angled impacts to the head. Those technologies include MIPS, Leatt’s 360° Turbine Tech, Kali’s Low Density Layer system, Shred’s Rotational Energy System, etc.

The problem is that our heads are soft and malleable, and the brain itself moves around inside a gelatinous ooze (cerebrospinal fluid), so the testing with a hard headform (which is the current method) may not be very appropriate for the human skull? One of the major things a helmet cannot prevent is the occurrence of the coup (brain impact) and coup-contrecoup (brain rebound) injuries, which can cause concussions, contusions, DIA’s (diffuse axonal injury) and even epidural hematoma.

They can dissipate and spread out the energy over a larger area, decrease the G’s from impact, and hopefully decrease the speed and force that the brain rebounds within the skull, to alleviate and lessen the severity of the concussion, though, in severe crashes/impacts, injuries will still happen. The brain always rebounds, that can’t be prevented, but we can slow things down and reduce the energy.