Today, Revel Bikes made history by introducing the “Rodeo,” the world’s first fully 3D-printed carbon fiber Downhill Bike. The Revel Rodeo is a multi-year passion project of Adam Miller (Revel Bikes), Chris Canfield (CBF suspension inventor), and Jordan Haffener (Revel Bikes Senior Engineer). The Rodeo was designed by Revel and manufactured in partnership with 3D Printing pioneer Arevo Inc. While purely a concept bike and not currently for sale, the Rodeo exists as a groundbreaking example of what is possible with modern additive manufacturing and a handful of extremely passionate people in the Bicycle Industry.

Take a moment to enjoy the story of the “Rodeo,” and feel free to share the Youtube link below on March 14th when the embargo is lifted.

Revel Bikes have made an impact since their inception in 2019 with the release of the Rail – A hard-charging, capable, 27.5” wheeled all-mountain bike and the Rascal – a nimble and ridiculously efficient trail 29’er. These two models put Revel on the map for innovative suspension design combined with their unique understanding of geometry from years of making titanium hardtails. Utilizing the tried and proven CBF™ Suspension platform (US- patent 9,061,729), Revel bikes has set the bar high for what is expected from a modern full-suspension mountain bike, and they continue to raise that bar with more model releases.

Revel’s’ enthusiasm for innovation doesn’t stop at the frames, and in 2020 they introduced the world to the next generation of carbon wheels with the RW30 FusionFibertm wheels. Embracing the latest aerospace engineering practices, Revel launched the world’s first fully recyclable and environmentally responsible method of producing a carbon wheelset using a unique thermoplastic engineering process developed by CSS Composites. The FusionFiber RW30 can be produced without the need for harmful, brittle epoxy, and the result is a recyclable, high-performance composite rim that is significantly more durable, lighter, and overall a better riding wheel than other carbon wheels on the market.

Implementing FusionFiber for components manufacturing redefines what is possible when you look outside of the industry standards for production, and that is just what Revel is doing with their newest passion project – The Rodeo.

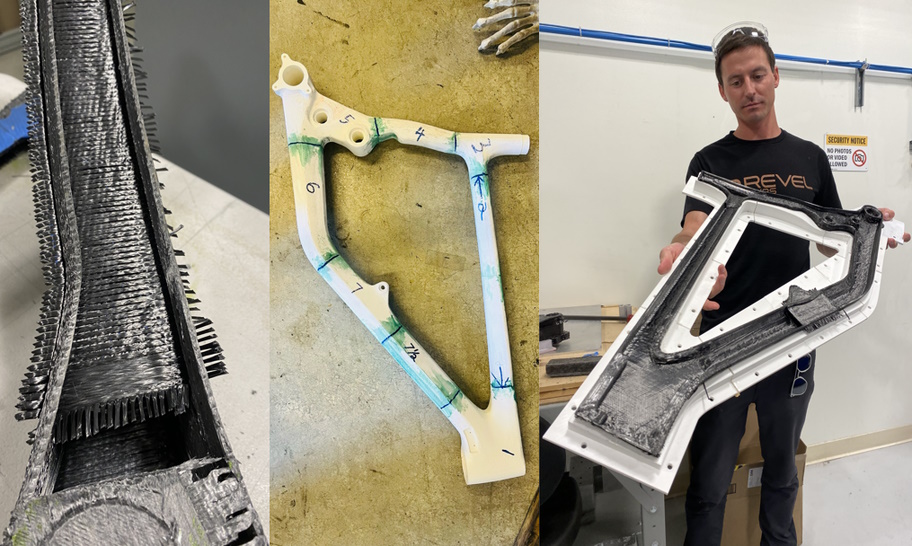

What started as a conversation between Adam Miller (Revel Bikes) and Chris Canfield (Inventor of CBF) in a coffee shop while waiting out a rain spell before a ride soon became tangible as they explored options to create a fully functional carbon downhill bike without the typical methods of manufacturing. Ignited with fire to bring something new to the cycling industry, Revel was introduced to Arevo Inc. – Pioneers in the additive manufacturing space and has already brought their own fully functional 3D printed bike to market. When the opportunity presented itself to begin the development of Revel’s own 3D-printed frame – they saddled up and got to work on a prototype Downhill frame. Jordan Haffener (Revel Bikes Senior Engineer) worked closely with Arevo at their facility in Silicon Valley to develop dozens of prototypes before landing on a design that passed muster. Designing a Downhill bike is one of the most ambitious undertakings for any brand because they experience abuse unlike any other, from massive drops, high-speed G-outs, and lateral stress from aggressive cornering; they demand durability and reliability to withstand seasons of riding.

The Rodeo is just a concept for now. Still, it serves as an example of conviction, innovation, and what is possible with current technology and what could be a reality in the future. It’s hard not to get excited about the prospect of a 3D-printed carbon bike made here in the United States, and the ramifications could mean incredibly improved prototyping and development processes for bike brands, safer conditions in production facilities, significant environmental benefits, and greater customization for the rider at better costs. Revel believes that this method of frame production could be the future for carbon bicycle manufacturing, and the Rodeo is proof that this is a real possibility that could become more of a reality for practical, reasonable-cost full suspension mountain bikes with continued technological advancements. A 3D-printed carbon mountain bike is doable, and with further innovation, there is even the potential for this thermoplastic composite material to be fully recyclable.

For now, this technology is too new to bring this bike to the masses. The entire process is incredibly time and energy-consuming, not to mention prohibitively expensive, and it is not realistic to bring The Rodeo to production at this time. But as innovations in additive manufacturing and thermoplastic technology continue, the possibilities of mountain bikes like this coming to market become very real.

Why a DH Bike?

Starting with a DH bike will allow Revel to trickle down what they learn during the R&D process to make the entire process more efficient for future large-scale production of other models, and they hope that starting with such a daunting task will encourage other brands in the industry to explore the potential that this method has to offer.

A Downhill bike needs to be overbuilt – the construction can have no compromises, but weight is also not a huge factor to consider. Although having a lightweight bike will aid in maneuverability, a fine line must be navigated between weight and structural integrity, which kept Jordan and the design team at Arevo hard at work while developing a bike that Revel felt comfortable putting to the test.

A Worlds First

3D printing is being used everywhere. Most recently, there has been a huge surge of companies taking the additive manufacturing route for various components and even tube junctions on frames. Revel sought out Arevo and their technology because they have developed a method of 3D printing structurally sound composite products for the intended use. Revel jumped at the chance to see their dream materialize and push the limits of innovation. The Rodeo is the world’s first 3D-printed, thermoplastic carbon fiber mountain bike and the world’s first carbon CBFtm suspension downhill bike. Although just a concept, the Rodeo is proving what is possible.

Why The Rodeo?

Revel Bikes is based in Carbondale, Colorado. During the summer months, Carbondale hosts a weekly rodeo event every Thursday, and the Revel crew is often found hanging out at the rodeo after a post-workday bike ride. They even have an official company party at the rodeo every summer, and a downhill bike made in America just made sense to be named the Rodeo.

{ 0 comments… add one now }